bulk Shrinkage Testing|textured yarn shrinkage : wholesaler By conducting a shrinkage test using standard methods like JIS L1909, ISO6330/5077, or FZ/T70009, you can accurately predict how much your fabric will shrink after washing or drying. This information is essential for .

WEBWelComix BlockBuster Comics. Tufos Adult Comics Read Online Download Free In PDF Format With High Quality Images. All Tufos Latest Episodes For Free.

{plog:ftitle_list}

WEBCoach Nicholas 'guerri' Nogueira. Info. Roster. Matches. Events. Achievements. For core. For team. Get the complete overview of FURIA's current lineup, upcoming matches, recent results and much more.

3.1.1 bulk shrinkage, n—a measure of potential stretch and power of stretch yarns or a measure of bulk of textured-set yarns. 3.1.2 crimp contraction, n—an indicator of crimp capacity or a characterization of a yarn’s ability to contract under tension. 1.1 This test method is used to determine the shrinkage of yarns in skein form when treated in boiling water, dry heat, saturated steam, or solvents. This test method is .

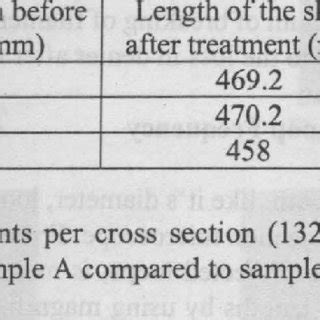

The change in length, depending on procedure, is a measure of skein shrinkage, crimp contraction, bulk shrinkage, or crimp recovery. 1.2 This test method applies to crimped, .The lengths of the skein under specified tension forces are used to calculate the value of bulk shrinkage, crimp contraction, skein shrinkage, or crimp recovery. 4.2 The test method offers .

Fabric quality testing and reports need for bulk fabric cutting for production orders. Fabric inspection report, shrinkage report, shade band reports. By conducting a shrinkage test using standard methods like JIS L1909, ISO6330/5077, or FZ/T70009, you can accurately predict how much your fabric will shrink after washing or drying. This information is essential for .The lengths of the skein under specified tension forces are used to calculate the value of bulk shrinkage, crimp contraction, skein shrinkage, or crimp recovery. 4.2 The test method offers . SmartShrink measures fabric shrinkage and calculates the test results. It avoids manual errors and makes the test more accurate and reliable. It automatically saves test data .

Application of this reliable and repeatable shrinkage test has led our research team to investigate the impact of programmed cure cycles on bulk properties, including shrinkage, for a selection of commercially available photo .

Many methods exist for measuring the shrinkage of cotton fabrics and garments. The most reliable methods use a system that properly prepares the sample for the test, agitates the goods without tensions or restrictions on the fabric, and .

(206°F)) is recommended. Only bulk shrinkage is calculated. 5.7 This test method for the measurement of bulk properties is not recommended for acceptance testing of commercial shipments because of lack of precision data. 5.7.1 If there are differences or practical significance be-tween reported test results for two laboratories (or more),Complete testing results are available in the OMNICHROMA Flow BULK Technical Report. Strength Esthetics Low Shrinkage OMNICHROMA Flow BULK exhibits low polymerization shrinkage compared to many other commercially . Synthetic fibers, like nylon, often shrink when heated. But shrinkage can be reduced if fabrics are heat-set during production. Nevertheless, it’s unrealistic to expect a zero shrinkage rate. Whatever fabric you’re using . How to do a fabric shrinkage test. To address fabric shrinkage, common inspection methods include dry steaming and washing. For example, in a wash test, the process and method for testing shrinkage rate are as follows: Sampling: Take a sample from the same batch of fabric, at least 5 meters from the start of the roll.

Bis-EFMA resin systems exhibited lower volumetric polymerization shrinkage (about 3-5%), higher curing depth (>6 mm in specific proportions), mechanical properties (flexural strength of 120-130 MPa, etc.), and microtensile bonding strength (>27.8 MPa), which were comparable or superior to Bis-GMA or commercial composites. Herein, we believe . For Class G cement, Goboncan and Dillenbeck 2003 showed in their laboratory-scale high-pressure and high-temperature cement shrinkage tests that the bulk shrinkage volume was 0.1% at 100 h after . This study aimed to evaluate volumetric polymerization shrinkage, degree of conversion and Vickers hardness of four bulk-fill resin composites light-activated with their dedicated light curing units (LCUs). Four groups were evaluated, according to the type of composite and curing mode: Tetric EvoCer .Polymerization shrinkage test. A total of 50 specimens were prepared for the polymerization volumetric shrinkage test. Specimens were divided into five groups (n = 10/group) representing the tested resin composites. The test setup included a white Teflon frame 4-mm diameter and 4-mm height that was used to circumscribe the resin composite .

Ultrasonic testing of concrete is an in-situ test to measure the thickness of concrete and tunnel linings, and to determine localized defects such as voids and honeycombing and delaminations. Ultrasonic testing is also used to detect objects like pipes .Measuring the Shrinkage of Fabrics & Garments. Many methods exist for measuring the shrinkage of cotton fabrics and garments. The most reliable methods use a system that properly prepares the sample for the test, agitates the goods without tensions or restrictions on the fabric, and measures the results accurately. Textile shrinkage testing is an essential process in the textile industry.It determines the amount of fabric shrinkage during washing, drying, or ironing. This information is crucial for manufacturers to ensure that their products meet quality standards and for designers to predict how a garment will fit after laundering. Without proper testing, fabrics can shrink .

Data were analyzed using one-way analysis of variance (ANOVA) and Tukey’s test. Results: . Yu et al stated that the mean shrinkage of bulk-fill composite resins ranges from 1.5% to 3.4%, while this range is 2.1% to 4.3% for conventional composites. The shrinkage rate of composite resins evaluated in our study was within the range for .The test to determine the shrinkage limit is ASTM International D4943. The shrinkage limit is much less commonly used than the liquid and plastic limits. 2.4.2.2. Plastic Limit. The plastic limit (PL) is the water content where soil transitions between brittle and plastic behavior. A thread of soil is at its plastic limit when it begins to .1.1 This test method covers the measurement of the change in length of a tensioned skein of textured yarn due to change in crimp characteristics brought about by exposure to wet or dry heat. The change in length, depending on procedure, is a measure of skein shrinkage, crimp contraction, bulk shrinkage, or crimp recovery.

(206°F)) is recommended. Only bulk shrinkage is calculated. 5.7 This test method for the measurement of bulk properties is not recommended for acceptance testing of commercial shipments because of lack of precision data. 5.7.1 If there are differences or practical significance be-tween reported test results for two laboratories (or more), The aim of this in vitro study was to evaluate the hardness and shrinkage stress (SS) of six bulk-fill resin composites. To evaluate microhardness (MH), ten 6 mm specimens were prepared using a metal mold .

yarn shrinkage test method

textured yarn shrinkage test

Part 2: Testing of well cements 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 bulk expansion increase in the external volume or dimensions of a cement sample 3.2 bulk shrinkage decrease in the external volume or dimensions of a cement sample 3.3 hydration shrinkage

Model: TSS-1. Standards complaince: JTJ051-93, T0121-93, SL237-026-1999. Description. The shrinkage apparatus is used to test the minimum water content of cohesive soil when draining, linear shrinkage rate, bulk shrinkage, shrinkage coefficient. Linear shrinkage stress was evaluated for 300 s with the aid of a linear shrinkage device adapted to a Universal Testing Machine. For each composite group, seven additional specimens (2x2x25 mm) were made and Young's modulus was evaluated with a 3-point bending device adapted in a Universal Testing Machine with 0.5 mm/min crosshead speed and 50 .

textured yarn shrinkage

Determination of the liquid limit by a one-point cone penetration test. Determination of shrinkage limit. Determination of bulk density by direct measurement of an undisturbed sample. Determination of particle density using a large pyknometer (preserving jar). b) Deletion The alcohol and sand bath methods for the determination of moisture content.

shrinkage in boiling water pdf

This study aimed to evaluate the polymerization properties of bulk-fill materials (low and high-viscosity) by using high-intensity continuous light and intermittent photo-activation in terms of polymerization shrinkage stress and degree of conversion (DC). The following Bulk-fill and Conventional na . Just as a tailor must measure fabric before cutting to ensure a garment fits perfectly, engineers must assess the characteristics of the soil to guarantee a stable foundation for construction. The shrinkage limit, a critical property, indicates the moisture content at which soil transitions from a semi-solid to a solid state, reflecting its potential to change volume .The least shrinkage was presented for Venus bulk fill, this was inconsistent with the studies of Lee and Rosatto et al. which showed that the consistency of the composite is a crucial aspect for determining the axial shrinkage. The low shrinkage of Venus bulk fill could be explained by its very low viscoelastic properties in comparison to the .The use of ‘peak bulk density’ as an alternative to the familiar shrinkage curve graphical construction (Fig. 1), in order to determine shrinkage limit, has been considered but does not apply to all the soils tested; as some did not produce a .

The use of thermoset composites has increased remarkably during the recent past in naval, automobile and aeronautical applications. Despite superior mechanical behaviour, certain problems, e.g. shape distortion, fibre buckling and matrix cracking, are induced in composite part, especially during fabrication due to the heterogeneous nature of such .

crimp shrinkage test

Conversely, the weft shrinkage is greater than the warp shrinkage. The test will give us accurate data on the expansion rate. We can use this as a basis for scaling the board sample’s length and width. . You do not need to control fabric wash shrinkage. After receiving the bulk fabric, go to the laundry and wash it as required. Control the .Objective: To evaluate degree of conversion (DC), Knoop microhardness (KHN), internal marginal adaptation (IA), and polymerization shrinkage stress (PS) of one conventional and four bulk-fill composites. Methods: Bulk-fill composites tested were Surefil SDR (SDR), Filtek Bulk-Fill (FBF), Tetric EvoCeram Bulk-Fill (TEC), and EverX Posterior (EXP).

Resultado da 30 de jul. de 2020 · Category. not specified. Statistics. Favorites. Posts filter. Gordinhas Gostosas. 30 Jul 2020, 08:11. Gordinha Delícia. 11 0 0.

bulk Shrinkage Testing|textured yarn shrinkage